Laser welding technology in new energy vehicle power battery

According to the information provided by the new energy website, since 1990, the lithium battery has the advantages of high energy density, high voltage, environmental protection, long life and fast charging, which has attracted the attention of new energy vehicles and other industries. As a lithium battery industry that provides power sources for new energy vehicles, it has huge market potential and is an important part of strategic development. It is estimated that the industry scale is expected to exceed 160 billion yuan in the next 5-10 years.

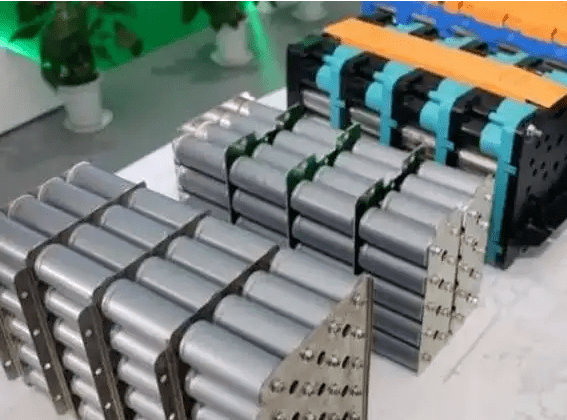

Power batteries are widely used, such as new energy vehicles, elevators, brakes, etc. Why do you say that power batteries are the core components of new energy vehicles? Because the power battery will loosen during the movement, the contact is poor, and the internal heat and expansion will cause a short circuit explosion. A good power battery can prevent this to a large extent, and its quality directly affects the performance of the entire car.

From the production of lithium battery cells to the assembly of PACK, it is a very critical step. Choosing the appropriate welding method and process will affect the overall cost, quality, safety and stability of the battery.

Laser welding is to use the excellent directionality and high power of the laser beam to work. The optical system is used to focus the laser beam in a small area, and a high energy density heat source area is formed at the welded part in a very short time. , By controlling parameters such as the width, energy, peak power and repetition rate of the laser pulse, the workpiece is melted to form a specific molten pool.

Welding advantages of power battery laser welding machine:

1. The speed of laser welding is fast, which can weld deeper seams, thereby effectively reducing material deformation;

2. It is suitable for welding thinner and finer materials without melting back;

3. In the process of laser welding, because of the focusing of the laser beam, the power density will increase, so that it can be positioned;

4. The deformation of the workpiece material to be welded is small, and the welding quality is superior;

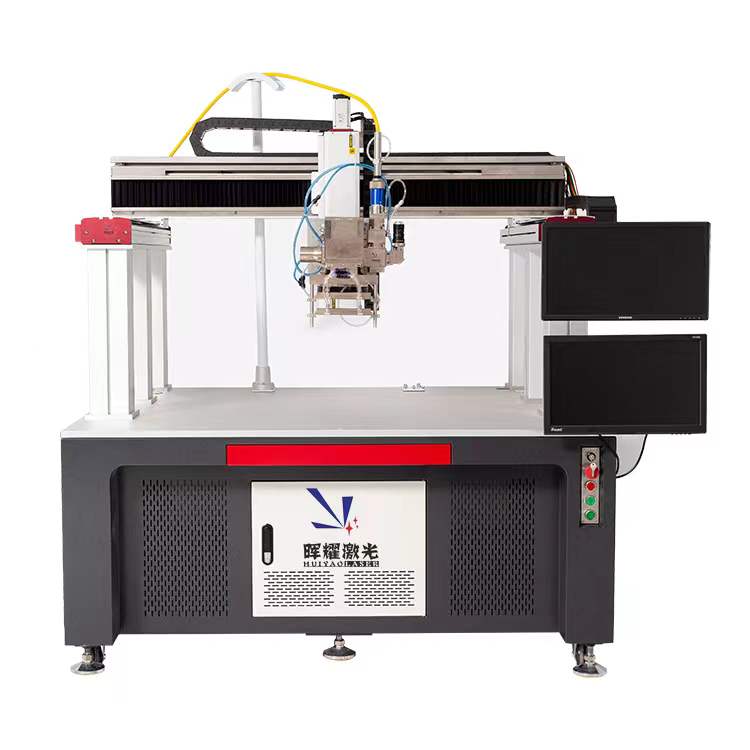

Huiyao Laser's gantry laser welding machine is specially used to weld power batteries, mainly suitable for welding of connecting pieces, nickel transfer, etc. watts, 3000 watts, 4000 watts, 6000 watts, and other specific powers), fiber optic galvanometer welding head or swing welding head, visual ranging system, chiller, CCD display, control software, etc.

Huiyao laser welding equipment is mainly used in the welding of new energy lithium battery packs: lithium battery to nickel, explosion-proof valve welding, battery tab welding, battery pole spot welding, battery pole welding, power battery shell and cover plate sealing welding , Large single square shell lithium battery and large polymer power battery module PACK welding, etc., to provide a better complete solution for automatic welding for the majority of new energy lithium electric welding equipment demand enterprises.

Contact us to discuss your requirements of Custom Tote Tennis Bag, roller skate backpack Wholesale, Custom logo Travel Pickleball Paddle bag. Our experienced sales team can help you identify the options that best suit your needs.